Single Cylinder Cone Crusher For Sale

Single-cylinder hydraulic cone crusher can be used in medium and fine crushing. Series single-cylinder hydraulic cone crusher is developed by adopting advanced crushing technology and integrating mechanical, hydraulic, electrical and intelligent control, internet control system and other technologies. It has optimized crushing cavity, with large crushing ratio, high efficiency, low energy consumption, uniform product size and other characteristics.

- 【Feeding Size】:≤560mm

- 【Output Size】: ≥5mm

- 【Capacity】: 30-1300T/H

- 【Crushing materials】: River pebbles, granite, basalt, iron ore, limestone, quartzite, pyroxene, iron ore, gold ore, copper ore and other types of ores.

- 【Applications】:It is widely used in various industries such as mining, metallurgy, coal mining, recycling of garbage and construction waste, civil engineering, highway and railroad construction, building construction, water conservancy and chemical industry.

The single cylinder hydraulic cone crusher’s powerful crushing capacity and wide applicability make it also suitable for a variety of other materials, such as glass, ceramic raw materials, and so on. However, in the specific application, it is also necessary to consider the hardness, humidity, particle size and other factors of the material, as well as the model of the crusher, the processing capacity and other technical parameters, in order to ensure the crushing effect and stable operation of the equipment.

In the hydraulic system of single-cylinder cone crusher, a kind of oil pump with bi-directional operation is generally used to control the button to make the oil pump rotate forward and reverse, and when the oil pump is rotating forward and reverse, the oil in the hydraulic cylinder at the bottom is pumped in or sucked out, which makes the main shaft move up and down.

Type of Single Cylinder Cone Crusher for Sale – Single Equipment

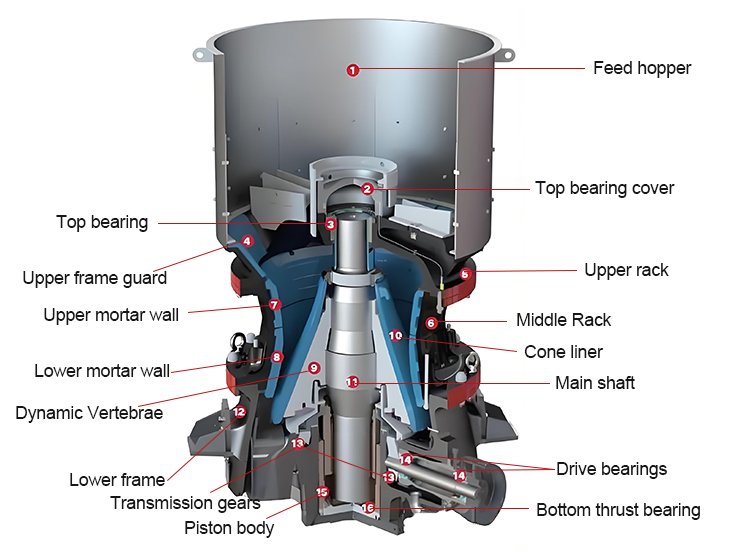

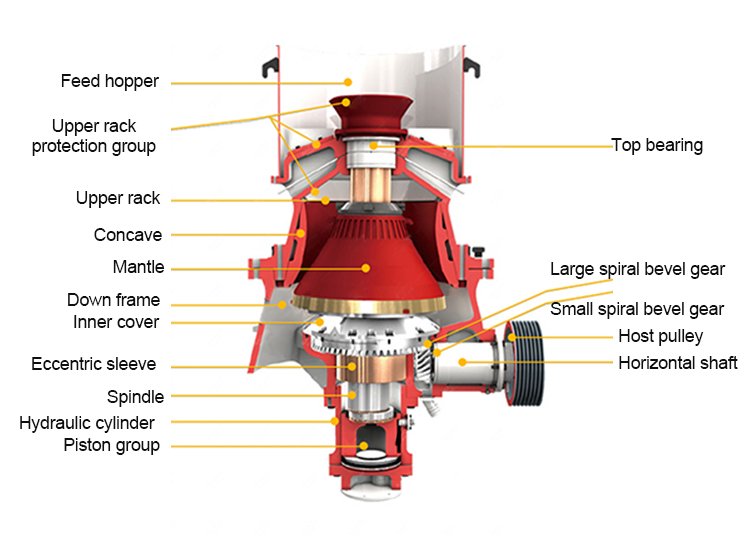

Single-cylinder hydraulic cone crusher is mainly composed of transmission part, eccentric sleeve part, crushing cone part, upper frame part, hydraulic cylinder part, hydraulic lubrication system, etc. The structure is simple and compact, easy to operate and maintain.

Single Cylinder Cone Crusher makes the whole powder making process more efficient and convenient with its advantages of compact structure, smooth operation, etc., and obtains more ideal grinding effect, . Applying the single cylinder cone crusher to the production line can improve the production process and production efficiency. It can also realize sterilization and cleaning to meet the requirements of modern powder making industry for light washing.

Note: The output will vary depending on different materials, feed particle size and other factors.

The Single Cylinder Cone Crusher can be customized according to production capacity, geography, climate and other factors, and the color can be customized according to customer requirements.

| Model | Cavity | Max feeding size (mm) | Discharge port corresponding to the output(t/h) | ||||||||||||||

| 6mm | 8mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 44mm | 51mm | 57mm | 64mm | 71mm | |||

| DP100 | Medium | 105 | 55-60 | 60-85 | 65-95 | 70-100 | 75-90 | ||||||||||

| Medium fine | 85 | 45-50 | 50-70 | 55-80 | 60-85 | 65-90 | 65-80 | ||||||||||

| Extra fine | 32 | 40-55 | 40-60 | 45-70 | 55-75 | 60-75 | 65 | ||||||||||

| DP430 | Extra coarse | 185 | 69-108 | 75-150 | 80-161 | 86-171 | 91-182 | 104-208/ | 115-208 | ||||||||

| Coarse | 145 | 66-131 | 71-142 | 76-152 | 81-162 | 86-173 | 98-197 | 109-150 | |||||||||

| Medium coarse | 115 | 57 | 62-140 | 67-151 | 72-162 | 77-173 | 82-184 | 93-145 | |||||||||

| Medium | 90 | 64-84 | 69-131 | 75-142 | 80-152 | 86-162 | 91-154 | 104 | |||||||||

| Medium fine | 75 | 61 | 65-106 | 70-115 | 76-124 | 81-126 | 87-114 | 92 | |||||||||

| Fine | 50 | 48-78 | 51-83 | 54–88 | 59-96 | 63-103 | 68-105 | 72-95 | 77 | ||||||||

| Extra fine | 35 | 70-90 ,80%<5mm-5.6mm | |||||||||||||||

| DP440 | Extra coarse | 215 | 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 | ||||||||

| Coarse | 175 | 101 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 | ||||||||

| Medium coarse | 140 | 97-122 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 | |||||||||

| Medium | 110 | 117-187 | 126-278 | 136-298 | 145-318 | 154-339 | 175-281 | 194 | |||||||||

| Medium fine | 85 | 114 | 124-227 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 | |||||||||

| Fine | 70 | 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 | ||||||||

| Extra fine | 38 | 100-125, 80%<6mm-7.5mm | |||||||||||||||

| DP660 | Extra coarse | 270 | 177 | 190-338 | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 | |||||||

| Extra coarse | 235 | 174-194 | 187-374 | 200-488 | 212-519 | 242-592 | 268-654 | 293-521 | 323-359 | ||||||||

| Coarse | 215 | 171-190 | 184-367 | 196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 | ||||||||

| Medium coarse | 175 | 162-253 | 174-426 | 186-455 | 198-484 | 226-552 | 249-499 | 273-364 | |||||||||

| Medium | 135 | 197-295 | 211-440 | 226-470 | 240-500 | 274-502 | 302-403 | ||||||||||

| Medium fine | 115 | 192 | 207-369 | 222-396 | 237-423 | 252-450 | 287-451 | 318-363 | |||||||||

| Fine | 90 | 195-304 | 210-328 | 225-352 | 241-376 | 256-400 | 292-401 | 323 | |||||||||

| Extra fine | 65 | 211-293 | 227-316 | 244-298 | 261-290 | ||||||||||||

| DP870 | Extra coarse | 300 | 448-588 | 477-849 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 | ||||||

| Coarse | 240 | 406 | 433-636 | 461-893 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | ||||||

| Medium coarse | 195 | 380-440 | 406-723 | 432-837 | 492-954 | 544-1055 | 596-1155 | 657-1272 | 708-1373 | 769-1370 | 821-1206 | ||||||

| Medium | 155 | 400-563 | 428-786 | 455-836 | 519-953 | 573-1054 | 628-1154 | 692-1271 | 746-1372 | 810-1248 | 865-1098 | ||||||

| Medium fine | 100 | 379-424 | 407-716 | 434-765 | 462-814 | 527-928 | 852-942 | 638-789 | 702 | ||||||||

| Fine | 90 | 357-395 | 385-656 | 414-704 | 442-752 | 470-800 | 535-912 | 592-857 | 649-718 | ||||||||

| Extra fine | 80 | 280-405 | 304-517 | 328-558 | 352-598 | 376-639 | 400-680 | 455-775 | 503-758 | 551-669 | |||||||

Features of Single Cylinder Cone Crusher

- High crushing efficiency: special crushing cavity and reasonable crushing stroke, crushing speed, pendulum frequency and layer compression crushing to bring higher output, greater crushing ratio, the finished product has a high proportion of cubic stone, pin flake stone is less, and the grain size is uniform.

- Self-protecting, interchangeable cavities: Rugged equipment construction and unique overload protection system ensure long term operation in the toughest hard rock crushing applications. Simply replacing the fixed cone can achieve a variety of cavity shapes for medium to fine crushing, adapting to different material size requirements.

- Reliable hydraulics and lubrication system: Positive pressure dust protection system ensures clean lubrication system at all times, and the double-insurance control of the hydraulics and lubrication system ensures overload protection and good bearing lubrication to minimize equipment failure.

- Easy maintenance: simple structure, stable performance, not easy to fail. Most of the parts can be disassembled and assembled at the upper and side, which can reduce the labor intensity of workers and improve the construction effect.

- Automatic design, easy to operate: high degree of automation, simple operation, even ordinary operators can quickly master.

Working Principle of Single Cylinder Cone Crusher

When the Single Cylinder Cone Crusher works, the motor drives the pinion gear of the crusher, the pinion gear drives the large gear, the large gear assembly drives the eccentric sleeve, and then the eccentric sleeve drives the moving cone part to do rotary swing, thus realizing continuous extrusion and crushing. When the material is added to the crushing chamber, the main shaft assembly rotates slowly in the eccentric copper bushing under the resistance of the material. The material is squeezed and crushed by the swinging inner cone, and the crushed material is discharged from the discharge port. The hydraulic cylinder at the bottom of the cone pushes the main shaft to drive the cone up and down, adjusting the distance between the cone and the fixed cone liner, thus controlling the size of the product.

Single Cylinder Cone Crusher Application in Crushing Plants

Single Cylinder Cone Crusher is widely used in the following fields:

Mining mines: Single Cylinder Cone Crusher crushes the mined ores to improve the beneficiation efficiency and metal recovery rate.

Building materials: crushing limestone, granite, etc. for manufacturing building materials such as sand, gravel and aggregate.

Chemical industry: Single Cylinder Cone Crusher is used to crush various kinds of coal, coke, gypsum and other chemical raw materials.

Water conservancy project: to provide sand and gravel materials required for water conservancy project construction.

Highway and railroad construction: Single Cylinder Cone Crusher crushes various road base materials such as stone and gravel, and the crushed materials are used for laying road base and pavement.

Metallurgical industry: crushing scrap steel, scrap iron, slag and other metal ores to provide raw materials for smelting.

What Should You Consider When Choosing Single Cylinder Cone Crusher?

If you are planning to buy a Single Cylinder Cone Crusher, then you need to consider many factors in advance, such as capacity, feed size, discharge aggregate size, application, price, service, return and so on. Here I have listed a few important parts for your reference:

Feeding size

The first thing you should consider is the feed size. Customers should probably know the size of the material aggregate before crushing. Because customized Single Cylinder Cone Crusher models are mainly divided according to the feed size.

Capacity

Capacity should also be one of the factors to consider. If you plan to crush a large amount of aggregate in a short period of time, it is better to choose a large capacity crusher. If there is enough time, a smaller size crusher may be more cost effective.

Price

Single Cylinder Cone Crusher cost is the most important aspect for customers to consider. It is very important for customers to choose a Single Cylinder Cone Crusher with the best price and within their budget. Chunlei offers different models of crushers with different prices. Please contact us and get the latest Single Cylinder Cone Crusher price.

Service

For mining machinery industry, choosing a reliable and serviceable single-cylinder hydraulic cone crusher manufacturer is very important for customers. Crushing production line is a complete set of solutions customized for customers. Therefore, it needs constant communication, follow-up and feedback. The best service can help customers save a lot of maintenance after-sales service costs.

For the mining industry, especially for large-scale mining machinery, it is especially important for customers to choose a reliable and well-served Single Cylinder Cone Crusher manufacturer. The crushing line is a complete solution customized for the customer. Therefore, both parties need constant communication, follow-up and feedback. Meticulous service can help customers save a lot of maintenance and after-sale costs.

What Can ChunLei Do for You About Single Cylinder Cone Crusher Service?

- Pre-sales service: 1.Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

- On-sale service: 1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

- After-sales service: 1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Customize Your crushing Solutions

Contact us now via email: info@miningmachinerys.com, or WhatsApp me, or fill in the form below.

1. Feeding Size.

2. What configuration do you need? (Crusher Type , VibratorScreening,Magnetic Separator, Sand Washing Machine, etc.)

3. ls there a Mining License?

4. Start time of project?

5. Other requirement.

Contact information: